Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Tel.: +86 13358378970

E-mail: sales6@saulplc.com

Jun. 25, 2023

1. Introduction to Simulator

Sampling time ∆ t=1s. The system is initially in a stable state, and the input flow that can be set is equal to the output flow (see table "Calculation", cell J21).

When t=0, it causes step interference to the discharge pipeline through the pump (see "Calculation" unit J24).

The actual level (present value) is calculated from the Mass balance (see page Calculations, cell C44: C2116). Obviously, in practical situations, there is a level transmitter that "reads" and communicates with the PV on the controller.

A Dead time can be put in the system (see "Calculation", cell J25) just to check the impact on the PID controller.

The algorithm PID determines the control action of the regulating valve, thereby changing the inlet flow rate.

The control valve has linear characteristics: Fin=% opening valve/100 * Fmax, in.

To disable differential actions, simply set Td=0 (refer to "Calculate" in cell J8), while to disable integral actions, set the value to 0 in cell J9.

2. Simulator adjustment

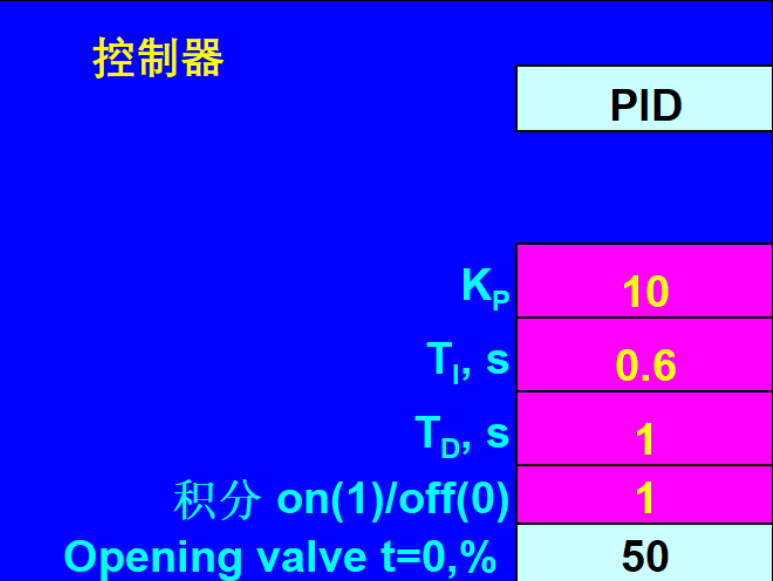

In the following data boxes, pink data can be modified, while blue data is calculated and cannot be modified.

The following are the settings for the controller parameters

Among them:

KP represents the proportional effect

TI, representing the integral action time

TD, represents the derivative action time

Integration on (1)/off (0), where 1 is for opening the integration effect and 0 is for closing the integration effect

Opening valve, which is the input flow divided by the output flow multiplied by 100 (refer to cells J21/J17 * 100)

Controller action, positive or negative feedback

Direct, if PV>SP, CO (controller output signal) increases

Indirect, when PV>SP, CO (controller output signal) decreases

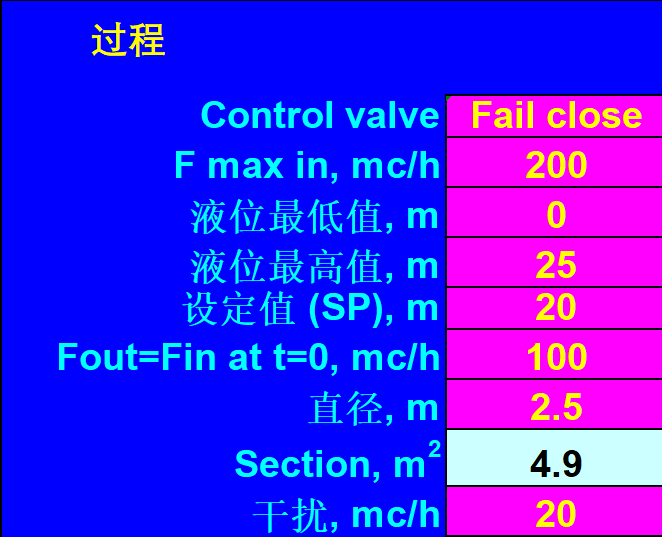

The following are the settings for process parameters

Among them:

Control valve, which is the type of valve

Fail close, represents the normally closed valve Fail open, represents the normally open valve

Fmax in, is the input flow rate

The lowest liquid level value represents the lowest liquid level value

The highest value of the liquid level, representing the highest value of the liquid level

Set value (SP), which is the set value

Fout=Fin, is the output flow rate

Diameter, is the diameter of the container, in meters

Section, is the dead zone section

Interference, steady-state error

Dead time is Dead time

3. PID debugging

For ease of debugging, the output graphics and parameter settings are now placed on the same page for easy viewing and parameter modification.

You can first fill in the type of controller based on the actual situation, whether it is positive or negative feedback, whether the type of control valve is a normally open or closed valve, the size of inlet and outlet flow, the high and low liquid levels of the storage tank, and other conditions. By adjusting the PID parameters, observe the changes in the graph.

Navigation

Add.: 9D, 9th Floor, Huguang Building, Hubin West Road, Siming District, Xiamen City, Fujian Province, China

Tel.: +86 13358378970

Mob.: +86 13358378970

E-mail: sales6@saulplc.com

WhatsApp: +86 13358378970

Wechat: +86 13358378970